What Are Physical Methods of Sterilization?

Sterilization is defined as a method of killing or removal of microorganisms from an object by proper physical or chemical methods. Sterilization is used for sterilization of culture media, sterile preparations, raw materials, auxiliary materials, and medical equipment.

Sterile objects do not contain any live microorganisms. For the determination of the sterilization level various factors are considered such as the properties of the articles to be sterilized, the effectiveness and economy of the sterilization method, and the integrity and stability of the articles after sterilization.

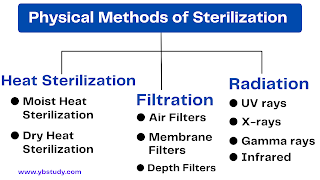

Most common physical methods of sterilization include moist heat sterilization, dry heat sterilization, radiation sterilization, and filter sterilization. More than one sterilization method can be applied depending on the characteristics of the object to be sterilized.

Physical Methods of Sterilization

i) Heat Sterilization

1) Dry heat sterilization method

- Dry heat sterilization is the most effective and widely used method of sterilization

- Dry heat sterilization uses very high temperatures to kill microorganisms such as bacterial spores, fungus, viruses, etc.

- Dry heat sterilization is used for the sterilization of materials that are difficult to sterilize by moist heat sterilization.

- Hot air oven and Incineration are worked on the principle of dry heat sterilization which generates very hot moisture-free air.

- Dry heat sterilization is used on items that cannot get wet such as Paper, oils, powders, metal instruments, glassware, and items wrapped in paper.

- Dry heat sterilization is of different types such as red heat, flaming, Incineration, dry hot air oven sterilization method.

- It has easy handling.

- It was cheap.

- It is not corrosive to metals and instruments.

- It allows the sterilization of powdery and non-aqueous substances and non-volatile viscous substances.

- Requires longer sterilization time, compared to moist heat, due to low heat penetration.

- It needs high temperatures and long exposure times and not all materials are going to withstand those temperatures for that long.

2) Moist heat sterilization method

- Moist heat sterilization is an effective and efficient method of sterilization where the steam removes microorganisms.

- The Autoclave is the device with which sterilization is carried out by pressurized steam. This sterilization process requires exposure inside for about 15 to 20 minutes at 121°C at 15 Psi.

- The advantages of moist steam sterilization are easy to control and monitor, microbicidal it has Rapid cycle time.

- At the same temperature, the effect of moist heat sterilization is better than that of dry heat sterilization, because, on the one hand, the protein in the cell has high water content and is easy to denature.

- On the other hand, high-temperature water vapor has a high penetrating power to proteins, thereby accelerating protein denaturation and rapid death.

- Material that can be sterilized by moist heat sterilization Textile material (gauze, compresses, bandages, cotton, swabs, surgical and non-surgical clothing), rubber and latex material (drains, teats, Guedell cannulas), instruments (tweezers, scissors, scalpels, instrument boxes), Needles, strong plastic such as baby bottles or syringes, tubes glass material, etc.

- Moist heat sterilization is different types: Pasteurization method, Boiling disinfection method, Intermittent sterilization method, pressure steam sterilization method.

- Fast heating and penetration. (speed)

- Destruction of bacteria and spores in a short time.

- high efficiency

- Leaves no toxic residue

- There is little deterioration of the exposed material.

- Easy drive.

- Economic. (low cost)

- Ease of process control. (it’s automated).

- Does not allow sterilization of solutions that form emulsions with water

- It is corrosive on certain metallic instruments.

- Deteriorates heat-sensitive materials such as adhesive dressings, bandage glue.

ii) Radiation

- This method refers to a method in which sterilized products are placed in gamma rays radiated by suitable radioactive sources or electron beams generated by suitable electron accelerators for ionizing radiation to kill microorganisms.

- The most commonly used method of this method is 60Co-γ-ray radiation sterilization.

- Here we can take advantage of the destructive capacity of some types of radiation, harmful to living beings, to eliminate microorganisms from the material or instruments that we want to sterilize.

- It is a very effective method, practically instantaneous, it is carried out at room temperature and pressure, which allows any material to be sterilized without suffering deterioration. A radiation source with extensive and special lead-shielded facilities and enormous security measures is needed.

- Its action depends on the type of radiation, the exposure time, and the dose (amount of radiation emitted on the material to be sterilized).

- Ionizing radiation has great penetrability and is used to sterilize thermolabile (thermosensitive) materials such as disposable syringes, probes, etc. They are used on an industrial scale due to their high costs.

- Ultraviolet rays affect the DNA molecules of microorganisms. They are poorly penetrating and are used for surface sterilization in operating rooms.

- The use of gamma rays is based on knowledge of atomic energy. This type of sterilization is applied to thermolabile products or materials and is of great importance in the industrial field. You can sterilize antibiotics, vaccines, food, etc.

iii) Filter Sterilization

- Filter Sterilization is the process of removal of unwanted organisms like bacteria, fungi, etc. from the liquid medium or from the air with the help of filters.

- It is divided into liquid filtration and air filtration

- The filter sterilization method uses a membrane filter with a certain pore size to prevent the passage of microorganisms and remove microorganisms in solution or in the air.

- This method is suitable for the sterilization of thermally unstable liquid medium (such as animal serum, protein, enzyme, vitamin, etc.) and gas in a small volume.

- Commonly used bacteria filters include membrane filter (0.45μm and 0.22μm pore size), HEPA filters, depth filters, ceramic filter, asbestos filter (Seitz filter), sintered glass filter, etc.

- Commonly used filters are made of Cellulose, nitrocellulose, asbestos, ceramic soil, Porcelain, Borosilicate, Diatomaceous earth, etc.

- It is used to sterilize oils, some types of ointments, ophthalmic solution, intravenous solution, diagnostic drugs, radiopharmaceuticals, cell culture media, and antibiotic and vitamin solutions.

- Also used for sterilization of heat-labile biological products such as serum, toxins, antibiotics, and air.

- The biggest advantage of filter sterilization is that it does not destroy the chemical composition of various substances in the medium.

Biological Indicators

- Biological indicators are the special type of live microorganisms which has resistance power to a specific sterilization process.

- Biological Indicators are also known as Bioindicators.

- Bioindicators are mostly living organisms such as microorganisms, plants, and animals.

- Bioindicators are used to confirm sterilization performance, verify the sterilization procedure, monitor the sterilization effect of the production process, etc.

- For the preparation of biological indicators, it is necessary to determine the characteristics of the microorganisms used.

- Preparation should be carried out according to certain procedures.

- Biological indicators contain a certain number of one or more spores, which attached to carriers, such as filter paper strips, glass slides, culture medium, stainless steel, plastic products, etc.

- To avoid contamination in bioindicators it should be packaged with appropriate materials, sealed in ampoules, and set validity period.

- The sterilization tolerance of the interested microorganism should be greater than that of all possible contaminating microorganisms in the product to be sterilized.

- The selected microbial strains should be non-pathogenic.

- The strain should be stable.

- It is easy to store.

- It should be the long shelf life

- Easy to cultivate.

- The most commonly used biological indicator for the moist heat sterilization method is Bacillus stearothermophilus spores.

- Spores of Bacillus stearothermophilus, such as ATCC 7953, NCTC 10 007, NCIMB 8157).

- The heat resistance capacity of this bacteria is very high.

- It completely killed at 121℃ for 19min.

- Clostridium sporogenes spores (Spores of Clostridium sporogenes such as NCTC 8594, NCIMB 8053, ATCC 7955) can also be used as a biological indicator for moist heat sterilization method.

- The most commonly used biological indicator for the dry heat sterilization method is Bacillus subtilis spores.

- Spores of Bacillus subtilis, such as NCIMB 8058, ATCC 9372).

- Escherichia coli endotoxin was used for depyrogenation verification, and the dosage should not be less than 1000 bacterial endotoxin units.

- The most commonly used biological indicator for radiation sterilization method is Bacillus pumilus spores.

- Spores of Bacillus pumilus, such as NCTC 10 327, NCIMB 10 692, ATCC 27 142).

- The number of viable spores per slice was 107-108,

- The microorganisms used for the sterilization process must exhibit greater resistance to radiation than Bacillus pumilus spores.

- Therefore, Bacillus pumilus spores can be used to monitor the sterilization process, but not to establish the sterilization radiation dose.

- The most commonly used biological indicator for filtration sterilization method is Pseudomonas diminuta

- Pseudomonas diminuta such as ATCC19 146, which is used for filters with a pore size of 0.22 μm.

- ATCC 14 756 for filters with a pore size of 0.45 μm.

Fermentation Links

- Vitamin B12 Production By Fermentation

- Ethanol Production By Fermentation

- What is Xanthan Gum, How it is produced by Fermentation

- What are Protease, Uses and Applications

- 5 Factors Affecting Fermentation Process

- What is Fermentation? Definition, History, Types, Advantages

- Uses of Enzymes in Food and Beverages

- What is Batch Sterilization: Process, Its Advantages, and Disadvantages

- Single Cell Proteins: Definition, History, Production, Examples, Applications of SCP

- Citric Acid Production- History Stages, Process, and Techniques

- Enzymes: Definition, History, Nature, Structure, Classification, Functions

- What are Enzymes: Functions of Enzymes

- What is Culture Media: Definition, Types, Uses, Examples

- What are Microorganisms? Definition, History, Characteristics, Importance